Wall & Cavity Drying: Reaching Full Drying Potential

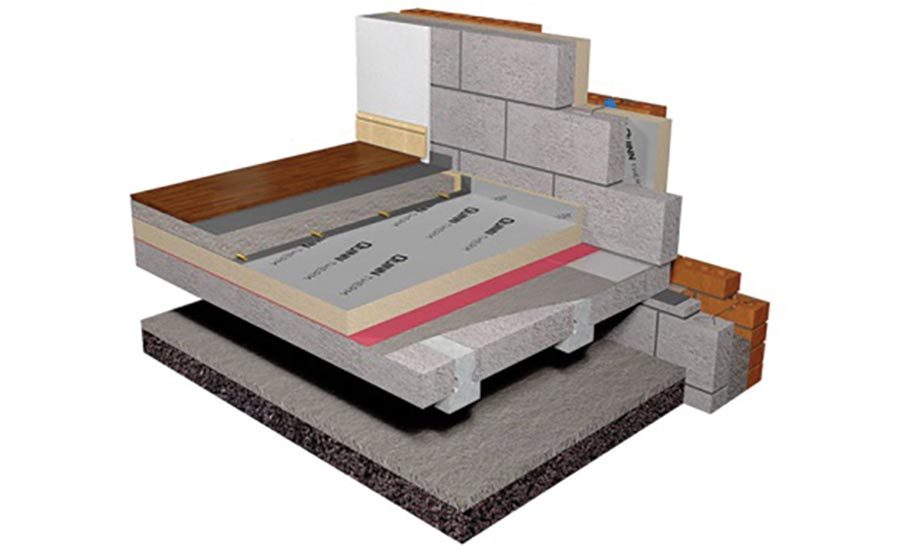

Suspended beam and block floor

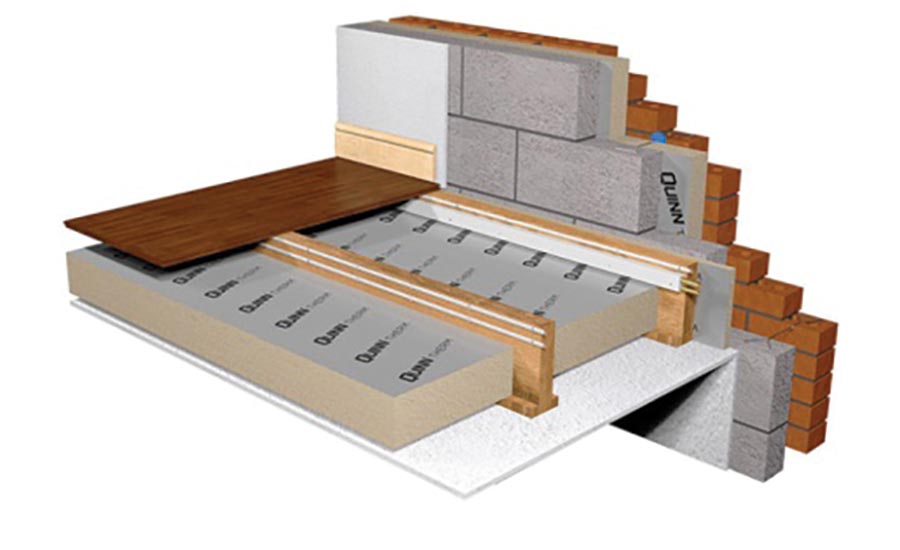

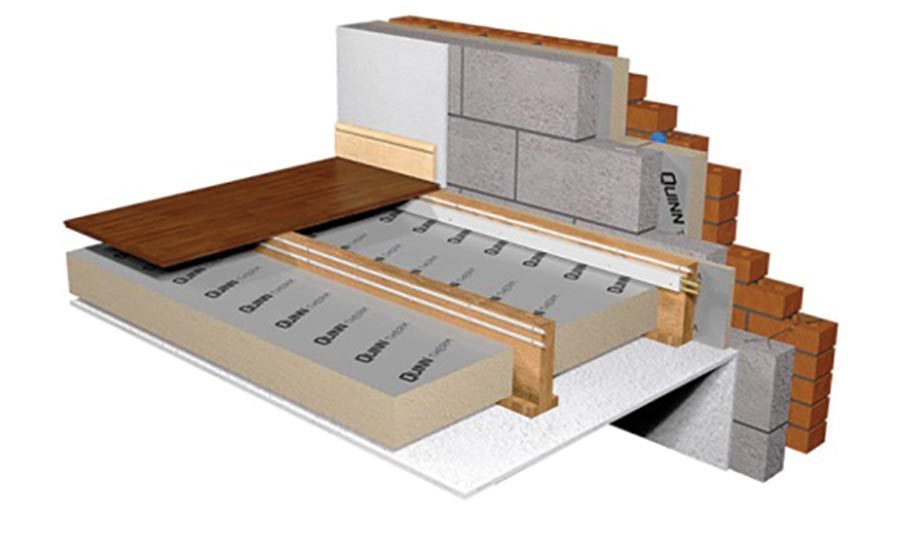

Suspended timber ground floor insulated between timber joists

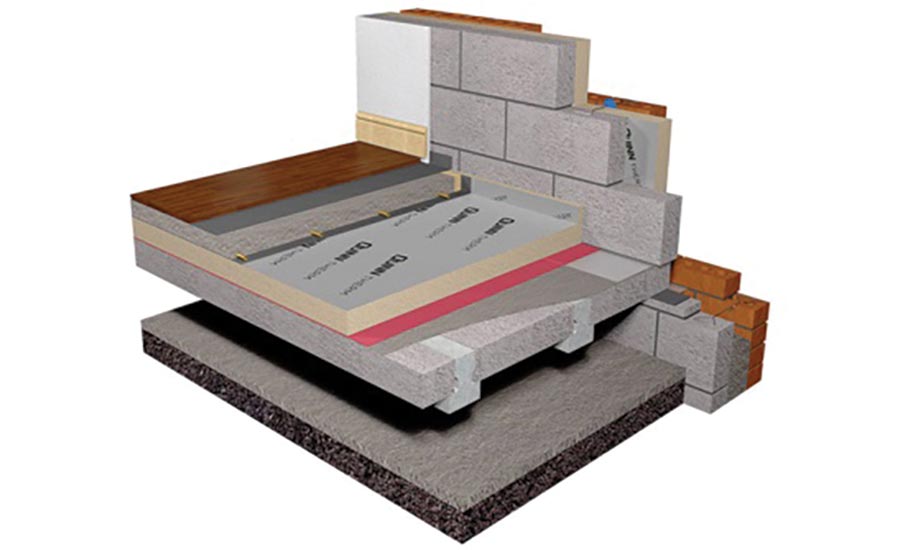

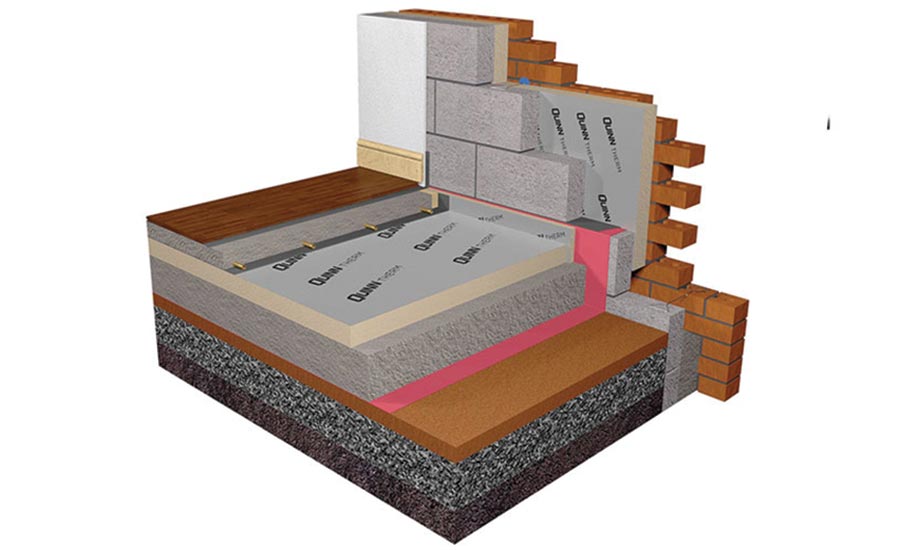

Solid ground floor: insulate above groundbearing slab

Double stud wall construction – high R-value wall assembly

Target drying of a subfloor space using heat systems

Injection drying of wall cavities using heat systems

Minimally invasive drying of a cavity wall

Injection drying of kitchen cabinetry

Targeted heating of walls

Targeted heating of floors

Construction projects are becoming more complex. As building materials become more advanced and focused on energy efficiency, the challenges facing a water damage practitioner are becoming more difficult and multifaceted. While traditional structures using materials such as wood, concrete, brick, and metal framing will always exist, we are now seeing a rise in the demand for eco-structures that are constructed using insulated concrete bases, insulated block walls, and a wide variety of insulation materials and vapor barriers. These materials and constructions add a new level of complexity for the water damage technician.

Drying wall cavities, crawlspaces, and other interstitial spaces has been an ongoing struggle throughout the years. In the past, water trapped inside these hard-to-reach spaces was often overlooked or not addressed correctly. Traditional equipment was designed to dry the air in the room and the surfaces of the materials rather than the water trapped within the multi-layered constructions. Contractors were forced to resort to elaborate, often labor-intensive, target-drying setups to try and focus energy directly onto the affected areas. In many cases the drying was prolonged and secondary damage occurred, resulting in costly strip-out, trashing baseboard, sheetrock, and insulation as well as damaging the project timeline. The goal of a water damage technician is to restore the structure to a pre-loss condition, and it is the role of equipment manufacturers to provide tools that enable this restoration process as building constructions continue to evolve and advance.

In recent years there has been a rise in the number of “injection drying systems” that deliver pressurized air into wall, ceiling, and interstitial spaces. These systems brought with them the capability to quickly and efficiently deliver dry air directly to the water and increase the success rates of drying—consequently reducing the amount of strip-out work required. These systems resulted in better levels of service for the client, a reduction in drying times, and a healthier result for everyone involved.

The addition of heat plays a key role in the speed of today’s jobs. Drying faster can indisputably eliminate or reduce strip out and lessen the risk of secondary damage. In the past, you could simply tent or chamber off an area to decrease the volume of air you are heating, subsequently pulling that hot air into your pressure drying system. Auxiliary heaters come in all shapes and sizes, and they vary in how they are fueled/powered. Let’s focus on the indoor-friendly electric options. Several manufacturers have begun to offer injection drying solutions that attach directly to the heat source. This concept has made it possible to get evenly distributed hot air into cavities and tight spaces without the need to heat the entire living space. These types of injectors are less intrusive and still provide a significant amount of warm, dry air with holes that are small enough to maintain fire-rated wall integrity. They also offer a base unit that adds a limited amount of noise to your environment.

Contractors can now deliver hot, dry airflow directly to the water, and it is this heat energy that increases the evaporation potential of the wet materials. These systems can be regulated to limit air-off temperatures, protecting sensitive materials and environments, and they can also limit the amount of amperage they pull from the mains supply—providing the flexibility and adaptability that is required from one claim to the next.

Modern equipment provides contractors with the flexibility to switch between various hose sizes and configurations—depending on the situation. In some cases, the contractor needs to take a minimally invasive approach, opting for smaller hose sizes (5/8”) and a smaller post-drying repair. In other cases, there is the freedom to open up a larger cross-sectional area and run hose sizes as large as 1½“, 4”, and 6”—maximizing airflow into the cavities and voids being targeted and further increasing your drying potential. The equipment autonomously adapts its power delivery to compensate for varying levels of back-pressure and restrictions to airflow, providing a safe and reliable tool that is specifically designed for that task.

These systems can be very effective, but what if demolition or holes in the material aren’t an option? How many times have you come across a claim where the homeowner had just endured a lengthy remodel and quite simply wouldn’t allow anyone to create a single hole or crack in a newly finished floor-to-ceiling tile-work? Conventional techniques in these cases wouldn’t make a dent in the drying project, and contractors need to get a little more creative.

Target drying is the concept behind the latest contender to step into the wall and cavity drying arena. These new target-drying mat systems connect directly to a precision auxiliary heater. Air movement is typically provided by the air movers you already have on the job. These “pre-fab reusable tents” are custom solutions to dry wall cavities, crawlspaces, or almost any hard-to-reach area. These lightweight options connect to your heat source and Velcro together. They maintain size and shape, and they evenly disperse hot, dry air over the entire affected area through tiny micro-jets. This patented technology breaks the boundary layer of moisture while constantly delivering energy to the water within the structure, thus speeding up the process with no holes or tear out necessary. You can easily move them, walk on them, connect them together for larger losses, or attach injectors to accomplish more invasive drying when necessary. The wall-specific drying mats are designed to inflate and hold themselves against the wall. Micro-jets along the entire surface of both wall and floor ensure even heating all the way to the sill plate. If you lose power, they fold down in an intentional pattern that allows them to resume correct positioning when the power returns. They come in a variety of setups, including perforated legs for drying in between joists or in crawlspaces. Depending on your environmental conditions and the severity of the loss, you may want to also place a dehumidifier nearby with the dry air directed toward your setup. This has proven highly effective on all types of construction, and the mat system is a great addition to your fleet.

No one tool can do every job. You can’t build a house with only a hammer, but you’d better have one in your tool box. The size and severity of the loss, indoor and outdoor environments, and even the access you have to the space you need to dry all affect which equipment you decide to employ on a job. Sometimes tear out and reconstruction are the only choice. Sometimes you don’t need to make a single hole. The best solution for every situation is to diversify your fleet. Hopefully now you have a better assessment of what options are available to your team.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!