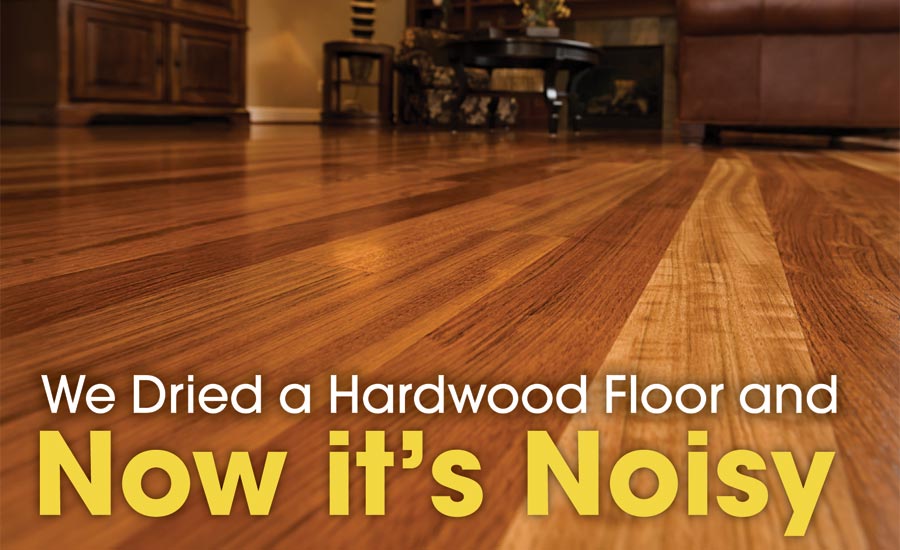

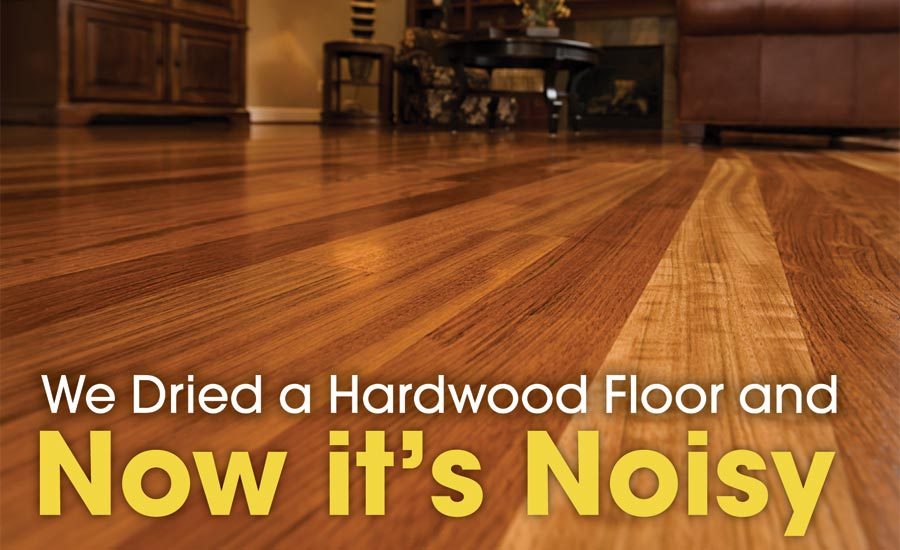

We Dried a Hardwood Floor and Now It's Noisy

Photos courtesy of Roy Reichow.

Photos courtesy of Roy Reichow.

Photos courtesy of Roy Reichow.

Photos courtesy of Roy Reichow.

Photos courtesy of Roy Reichow.

How many times have we gone into a water loss involving a hardwood floor and several months after you’ve completed the work there is now a noisy wood floor concern in the area of the water loss? As a certified wood floor inspector, I see this time after time and in many cases the water restoration professional is unaware of the characteristics of certain wood products.

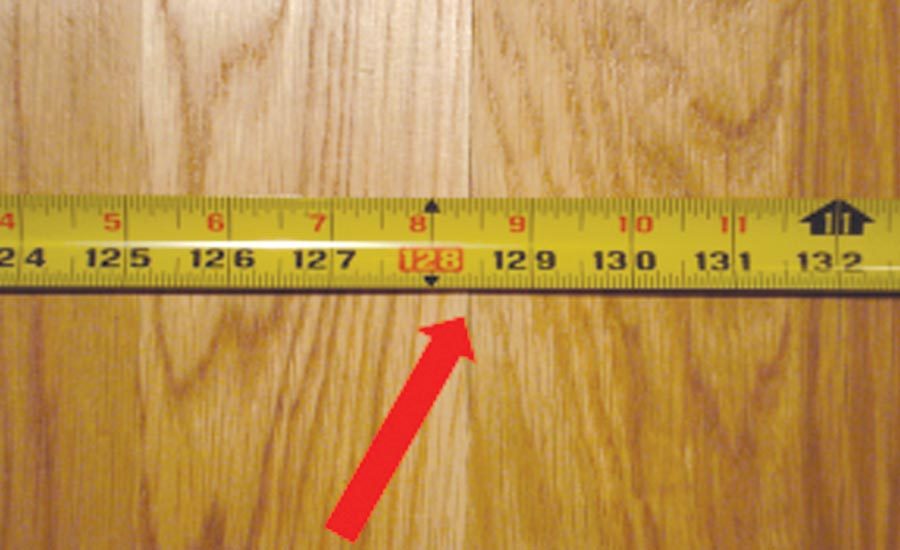

The first thing we must take in consideration is whether the floor is a solid or engineered wood floor. Moisture readings are required on a solid wood floor to determine how much of the wood floor has taken on moisture. For example, if the wood floor has increased by more than 10% moisture content, the wood floor has most likely swelled and is pushing the shouldering boards by 3/8” or more. This will create large gaps when the floor is totally dried and back to original moisture content. The simplest way to test for this is to take a 10 to 30 board width measurement. For example, if we have a 4-inch-wide material and measure 32 boards, it should equal 128 inches. However, if you obtain measurement of 128-7/16” wide when the floor dries back to normal, there will be a .015” gap between each board. These unsightly gaps were not present before the floor experienced the water exposure and will be a concern to the property owner.

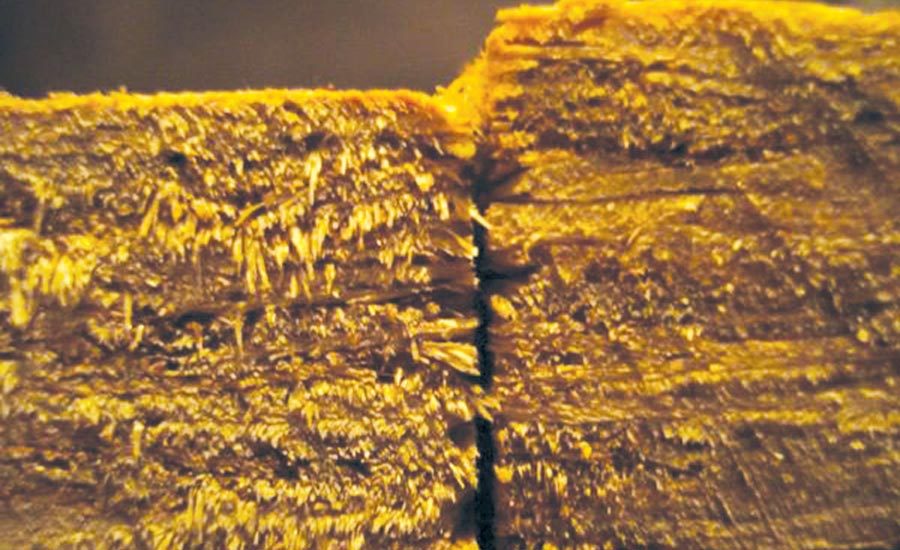

The second scenario is where the floor expanded and actually buckled in a small area as shown in the photograph of a 4- inch American Cherry floor. You can see from measuring blocks, the floor is now 7-1/4 inches for total loss for 3/4”. This is the reverse scenario of the example above, however the results are the same. There would be no way to successfully repair this wood floor. Therefore, the course of action would to remove and replace the solid wood floor so we would not experience as gapping concern.

SUBFLOORS

The latest trend in construction today is to use OSB subfloors and in many cases, the general contractors will use a commodity grade (low end) material to keep housing costs down. However, when these types of subfloors get wet they lose their ability for fastener retention once they are dried. This is due to the OSB panel decompression and swells in thickness. During the manufacturing process of the OSB, the thickness was produced at 0.705 inches. After moisture adsorption the panel swelled to 0.803 inches, nearly 0.100 inches, causing a reduction in fiber density and fastener retention abilities.

When this occurs, the floor fastener will become loose, allowing the floor to have vertical deflection, thus creating the noise related concern. If the OSB subfloor panels are high performance rated the noise concern rarely occurs due to the increase in fiber density and minimal swelling and deflection.

There is a rather simple field test to perform on OSB using an ice pick or awl. By depressing the ice pick into the OSB, if it penetrates through the other side by ¼ to ½ inch, this subfloor has lost its fastener retaining abilities. If the ice pick penetrates half the thickness of the panel material generally suggests it has normal fastening retention capabilities. If the ice pick penetrates through the OSB there are only two choices available for reinstallation of a wood floor. The first option would be is to remove existing OSB and replace it with a higher performance grade OSB. The second option is to use a full spread adhesive to glue and nail assist to install a new wood floor.

LOOSE FASTENING

The other thing the restoration professional should be aware of is how the original floor was installed. If the floor fasteners originally exceeded the floor manufacturer’s spacing recommendations, this would cause a loose floor after a water loss. It’s important for the restoration professional to have a couple rare earth magnets on hand and a handful of grout spacers to mark out the locations where the fasteners are placed in the floor. The standard spacing for solid hardwood strip floors (under 3”) is 8 to 10 inches apart, for plank floors (3” and over) the spacing is 6 to 8 inches apart. For most engineered wood floors, the fastener spacing will range between 4 to 6 inches apart. The NWFA.org website is a resource to obtain standards for floor fastening schedule. As the photo on the next page illustrates, the spacing is nearly 12 inches apart on a wide plank material and is out of specification. Combined with a lack of fasteners, decompression of OSB is a guaranteed red flag and the floor will most likely create noise when sub-floor and flooring reaches the original moisture content before the water loss.

CONCLUSION

It is vitally important for the restoration professional to observe all the conditions involving the wood floor beforehand and how the wood floor was originally assembled. Make note of the type of subfloor and condition at the time of water loss, and if you believe there is a chance the flooring is unsalvageable or will have recurring problems down the road, have a conversation with the adjuster. If you need some hard evidence, check out NWFA.org or contact your local NWFA inspector. Or share articles like this or others from R&R, or BNP sister publication Floor Coverings Installer Magazine. This will save you and potentially the insurance company time and money, and minimize the potential of noisy wood floors and liability in the future. The more you know, the better you can serve your customers!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!