The Ozone vs. Hydroxyl Debate

Which do you prefer for odor removal?

Images courtesy of: Odorox, International Ozone, & RamAir

Images courtesy of: Odorox, International Ozone, & RamAir

Images courtesy of: Odorox, International Ozone, & RamAir

Images courtesy of: Odorox, International Ozone, & RamAir

Images courtesy of: Odorox, International Ozone, & RamAir

Odor removal is a critical part of almost any restoration job. There are a variety of options available from masking agents to foggers to ozone and hydroxyl generators, and so on. Today, there is a rather big inner-industry debate being waged over the benefits and dangers of those latter two options. There is a clear advantage to using machines to eliminate odors from spaces and items rather than simply trying to mask them. During the RIA’s Forensics Restoration Conference in St. Louis last fall, there were people on both sides of the aisle talking about the effectiveness of both technologies – and the downsides.

This time around, odor removal experts are taking the stand to talk odor removal science to help you make an educated decision about which technology is right for your company.

Meet the Experts

David Hart (DH) – Team Ozone – A U.S. Army veteran, David has been involved in the carpet cleaning, and later – restoration industry, since finishing his service in 1991. A problem-solver at heart, David immediately picked up on some ways the duct cleaning process could be improved and in 2007, invented what is known today as the RamAir Duct Cleaning System. He has since invented the OzoGen 10kV High-Output Ozone Generator, and runs Guarantee Cleaning Services, Inc. in Bend, Ore.

Russ McCubbin (RM) – Neutral – Russ has been in the air and water purification equipment manufacturing industry for 25 years. International Ozone Technologies Group, Inc., of which Russ is president, was incorporated in June of 1999 and their first products were the Total Zone Ozone Generators, and a line of “ozonated” oil ointments. International Ozone has been private labeling ozone generators and hydroxyl generators for 12 years and has been named “Vendor of the Year” three times.

Tom McArdle (TM) – Team Hydroxyl – Heavily involved in odor removal education and training throughout the U.S., Tom is the Vice President of the Odorox Hydroxyl Group. Odorox technology was launched in 2008, and in just a few years gained credibility among restoration contractors around the U.S. Two U.S. patents were issued for the technology in 2012.

What is the basic science behind your technology?

DH: Ozone is created when oxygen molecules (O2) are ‘sliced’ in half; the single oxygen atoms (O1) bond with ambient O2 molecules, creating ozone (O3 molecules). Ozone generators also produce ozone using these two principles- UV light and Corona Discharge.

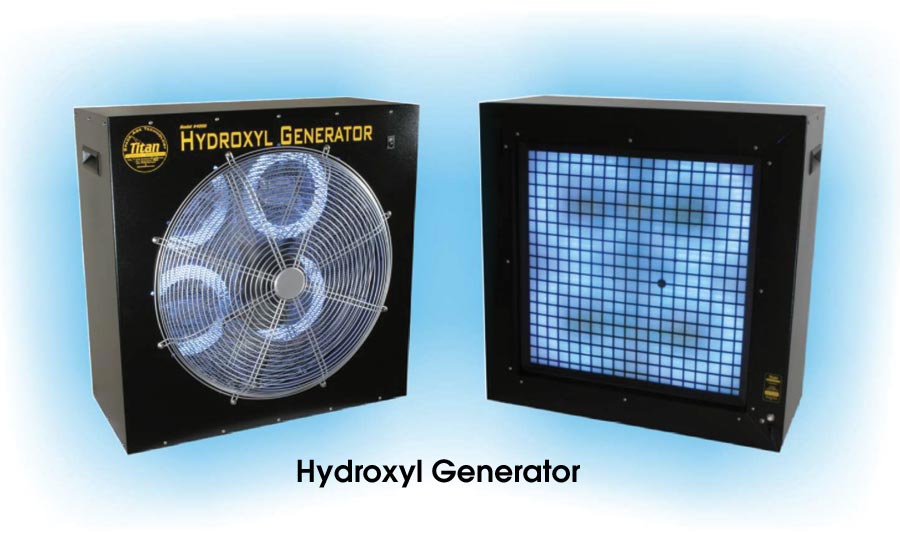

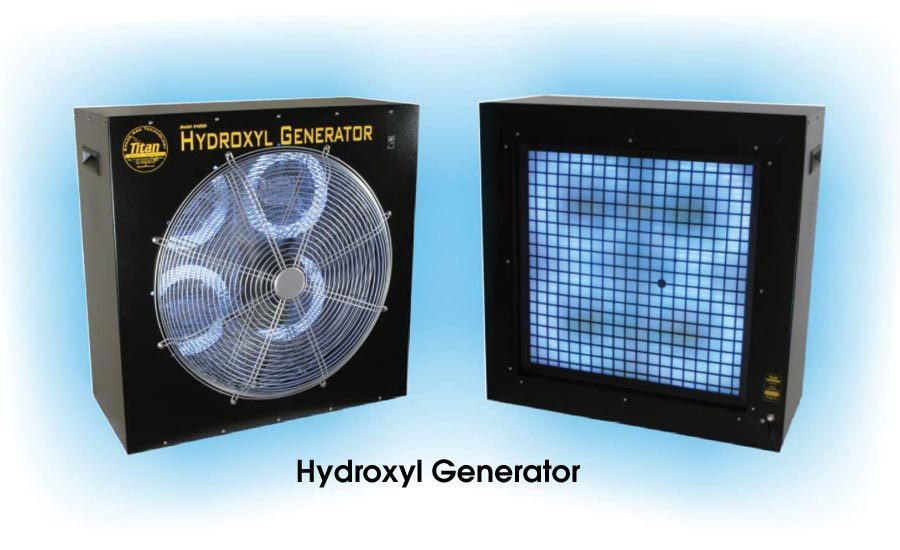

RM: Manmade ozone is produced by two separate processes. One is with UVC ultraviolet light in the 185-nanometer wavelength. The second process is called corona discharge, which produces higher concentrations of ozone than UVC, for faster deodorization. Titan produces hydroxyls by subjecting humidity in the air to UVA light in the 365 to 385 nanometer wavelengths in the presence of a catalyst, usually titanium dioxide. This photocatalyst process splits an H off of H2O leaving OH – hydroxyl and an H.

TM: The Odorox technology was patented because it is the only process able to produce hydroxyl radicals that exit the chamber of the machine to eliminate odors not just in the air, but more importantly, odors that have been adsorbed by contents and structures. This is done by using multiple high energy ultraviolet lights inside the chamber of the hydroxyl machines. It converts water naturally found in the air to hydroxyl radicals, as well as oxy and peroxy- radicals that exit the machine. The hydroxyl radicals that exit the machine are able to eliminate odors, not mask or otherwise cover them up, by disassembling all of the odor molecules including those found deep inside porous materials.

How effective is your respective technology at removing the most common odors restorers see – like smoke, mold, biohazard waste, etc?

DH: The way ozone permanently neutralizes odors is by oxidation. The third oxygen atom in the molecule is loosely bonded to the stable O2 molecule, detaching itself from the O2 when it comes into contact with a receptive odor molecule. This permanently alters the molecular structure of the odor molecule, rendering it odorless. It doesn’t simply cover/mask odors with another odor, it basically removes the odor from existence.

RM: Ozone is faster than hydroxyl at removing odors but must only be used in un-occupied areas. Ozone is great at removing any organic gaseous compound once the source has been removed. Ozone is great for use on mold, mildew, smoke, VOCs, bacteria, virus, etc… Titan hydroxyl generators are not for use as surface microbial kill. They are for airborne microbial kills only, but are great for area and content deodorization.

TM: Hydroxyls are the second strongest oxidant in the world behind atomic fluorine. They are one million times more reactive than ozone, which means they break down a much broader range of odors and pathogens compared to ozone. We have yet to find an odor that Odorox cannot break apart. However, the most difficult project is typically pet urine. This is not because the ammonia is hard to break apart - it’s easy. It’s because the pets were probably there for years and the urine has soaked deep into the flooring which makes it difficult for contractors to fully remove the source. It’s important to remember that disaster-related projects are different and there are always variables to consider when assessing a project. Proper training always helps.

3. What do you say to potential clients concerned about safety of hydroxyl/ozone?

DH: People (and rightly so) are leery of things they don’t understand. There are a few misconceptions out there regarding ozone and its safety.

Nobody has ever died from ozone exposure; however, thousands of people die every year from carbon monoxide poisoning. Carbon monoxide (CO) is toxic; yet we think nothing of standing around our car while it idles, walking down a busy street downtown during rush hour, etc. By simply educating our clients on the safety of ozone, their concerns dissipate.

RM: Ozone is only to be used in unoccupied areas with return to the area at least one hour after the machine has turned off. Ozone can bleach wet materials and damage natural rubber. If a homeowner cannot leave or a store cannot shut down, hydroxyl generators are the way to go.

TM: That is definitely understandable, and part of the reason why Odorox has invested significant time and expenses in safety testing. Examples of tests performed by independent parties include measuring the amount of hydroxyls produced (approx. 2,000,000 per cubic centimeter), a 13-week toxicity study performed on rats under strict FDA GLP guidelines (no adverse effects), the amount of ozone produced so contractors comply with OSHA standards, and testing performed by the FDA which now classifies Odorox as a Class II medical device for use in occupied areas.

What are some major differences you see between these two technologies?

DH: I have to chuckle whenever I think of when a friend of mine who was asked this very question (my friend is one of the world’s leaders in forensic restoration application and education). He said: “The difference, is that ozone works!” To be fair, hydroxyl machines do have their time and place… as people can work in the same room as an operating hydroxyl machine, whereas it’s recommended that the room/building be evacuated while ozone is in use. Despite this minor convenience, hydroxyl takes much longer to work, and isn’t nearly as effective. There’s nearly always an opportunity to run an ozone generator for a few hours, which will often produce considerably better results than what would take a hydroxyl machine days to accomplish.

RM: Both ozone and hydroxyl will remove odors – hydroxyl will just take longer.

TM: Hydroxyls are one million times more reactive than ozone. This means contractors can have the confidence of going to any project knowing that the Odorox will eliminate the odors regardless of what or where they may be - skunk, protein fires, VOCs, biohazard/trauma, fuel oils, curry, etc. Second, they are safe for both people and sensitive materials. It allows odors to be eliminated from all contents without the risk of damaging them - rubber, plastic, electronics, artwork, wet items, etc. Finally, hydroxyls don’t leave behind the residual chemical smell that is common with ozone. An advantage to ozone is that you can produce a very high concentration of ozone as compared to the amount of hydroxyls that can be produced. This means that even though hydroxyls are significantly more reactive than ozone, ozone may eliminate odors faster on certain projects because of the high concentration. For example, in a small area, if ozone takes 24 hours to eliminate the odors, hydroxyls would probably take 36.

Give one raving odor removal story where your technology was used.

DH: My company did a promotion a while back where we offered to treat one home for each local real estate company at no charge, just to show how effective it is. We called it our “Give us your stinkiest home” special. One of the responders to this promotion was a friendly agent who called in desperation, telling me they had a beautiful home that was priced right but absolutely would not sell. The home was previously owned by an older couple who had smoked cigarettes indoors for 20+ years. They cleaned the carpets, scrubbed the walls, and yet the cigarette smoke odor was still so strong it burned my throat within 30 seconds of entering the home. After a single treatment, the home was 100 percent odor free and sold a few weeks afterward.

TM: We have so many great large loss stories, it is tough to pick just one. One that pops out in my mind was a large condo in Manhattan affected by smoke from a fire outside. More than $1 billion dollars in artwork inside the condo was damaged by the smoke. A contractor brought in some hydroxyl machines, and simply running them in the condo restored all the artwork. It was 100 percent effective, and absolutely no risk of damaging the art.

6. Any closing arguments?

DH: Diversification is key in the cleaning industry. It doesn’t take much in the way of financial investment or training to add services like duct cleaning and ozone treatment to your business, and these services are among the most lucrative in the cleaning industry. Instead of contracting or referring it out, offer it yourself and reap the profits!

RM: We see equal sales of ozone vs. hydroxyl equipment – 50/50 split.

TM: The two biggest questions we get are how large of an area does one machine cover and how long it takes to work. Our general guideline is one machine will cover 1,000 - 1,500 square feet with ceiling height up to about 20 feet. Most jobs take three to four days. There are always variables that can change this, but it is important to understand 1,000 - 1,500 square feet is a very accurate number.

To know when the job is done, turn off the machines and go smell porous materials where you know the odor was present - drywall, cabinets, couches, clothes, etc. If the odor is gone, the job is done. If the odor is still there, run the machines longer or move them around.

There you have it. Both sides of the argument, and evidence proving both hydroxyl and ozone work to remove odors during restoration and remediation work. So ... which do you choose?

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!