Stick to What Works: Tapes of the Trade

The jobsite can be rough and dirty, so it’s critical to choose tapes that are durable and resilient to withstand the rigors of the job.

DS 154 Double-Sided Containment Tape is two tapes in one to help contractors cut steps, not corners, when building high-performance containment systems and air barriers.

Painter’s tape and duct tape can also be used together to build containment systems.

Often used for seaming, sealing and repairs, foil tapes deliver a permanent, airtight bond demanded for a job well done.

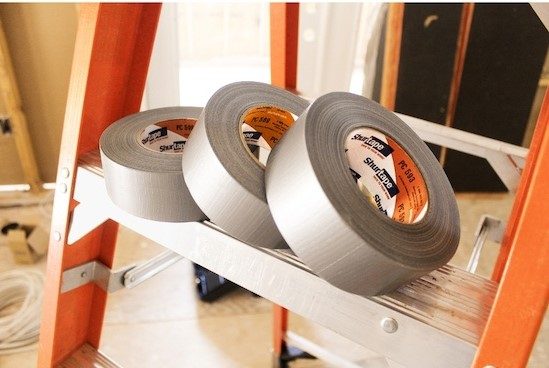

Offering a combination of strength and adhesion, duct tapes are a versatile tool that can be used for a variety of tasks around the jobsite.

From electrical and stucco to warning stripe and floor preservation, tape isn’t a one-size-fits-all solution – every toolbox should be stocked with a variety to tackle just about any job.

Shurtape’s DS 154 Double-Sided Containment Tape removes cleanly – in one step – when the job is done to save time and money.

Prepping for restoration, renovation, abatement and remodeling jobs is vital to delivering on-time completion and superior results. A key component to that prep work is arming yourself with the right tools for the job.

While that may include items like personal protective equipment, power tools, poly-sheeting and cleaning supplies, it’s also important not to overlook smaller, yet equally critical tools, like tape.

Tape is an essential tool for a variety of tasks around the jobsite. But remember…tape is not a one-size-fits-all solution. Picking the right tape could be a deciding factor in a job done well and a job requiring costly call-backs.

The Right Roll for the Job

There are several things to consider when picking the right roll for the job. The two most important considerations are environment and application.

Environment

From asbestos removal, disaster relief, fumigation and mold remediation to lead removal, clean-up of water, smoke and fire damage, and general remodeling and renovation jobs, no jobsite is the same.

Environmental factors like dirt, dust, humidity, moisture and temperature can have an impact on the performance – and ultimately the reliability – of the tape. Failure to consider surfaces to which you’ll be applying tape, the conditions at the jobsite, and even the time of year can lead to frustration and added work.

For the best results, look for tapes that are durable and resilient to withstand the environment, and as such, the rigors of the job.

Application

As mentioned, tape isn’t a one-size-fits-all tool. There are many options to choose from, each one bringing its own set of performance characteristics and recommended applications. Below are several tapes that may be used on the jobsite:

1. Painter’s & Masking Tapes

Often used for paint masking and protecting surfaces, painter’s and masking tapes can also be used for bundling, labeling and hanging temporary signs.

When selecting a painter’s or masking tape, consider the performance characteristics you may need, including easy unwind, quick stick, conformability, multi-surface performance, clean removability and UV resistance.

Painter’s and masking tapes are also used when building containments – understanding that the tape must hold strong enough to the surface to hold up to your containment, but still remove without damage is critical. Certain tapes are engineered for this specific application, and by picking these tapes, you can save time and money.

2. Foil Tapes

Typically used in HVAC work, foil tapes are handy for ductwork, metal and sheet metal repair, as well as for joining and sealing ductwork connections and seams.

Here, code compliance, ie. UL Listing, may be one of the most crucial factors to consider – especially as not using the right tape may result in failure of the inspection. Other features to consider are the tape’s ability to produce permanent, airtight and waterproof seals, as well as the tape’s ability to perform in a range of temperatures and environments.

3. Packaging & Strapping Tapes

Packaging and strapping tapes are the go-to for packaging and sealing boxes, but can also be used for general purpose bundling and holding applications.

These tapes are available in a range of grades, from light to heavy duty, so consider what you’re sealing when choosing. For example, heavier items may require a thicker and stronger tape, while light duty jobs may just require a tape designed with good adhesion characteristics.

4. Duct Tapes

A must-have for any toolbox, duct tapes are ideal for hanging poly-sheeting, general repairs, and patching, securing, sealing, wrapping, binding, bundling and goosenecking applications.

Building containments with duct tape is common, but demands a tape that can adhere very well to both the masking tape that is protecting the surface and to the poly-sheeting. Again, selecting a tape that is engineered specifically for this application can help save time and money.

When choosing a duct tape, determine whether you need aggressive adhesion and holding power, durability, performance in versatile environments and conditions, easy handling and tearability, and good conformability.

5. Double-Sided Tapes

Double-sided tapes are a great option for making quick work of building high-performance containment systems and critical air barriers.

Look for tapes that deliver aggressive adhesion and holding power, performance in wet and dry environments, easy handling and hand-tearability, good conformability, as well as clean removal without damage or residue.

6. Other Tapes

Other tapes that may be in the toolbox include electrical, stucco, barricade, warning stripe and floor preservation tapes. These are typically used around the jobsite for tasks such as splicing and binding wire harnesses, surface masking, color-coding, marking restricted areas, temporary floor marking and protection, and more.

Depending on the tape and the job, be sure to consider your needs around strength and durability, flexibility, resistance to UV, moisture, humidity and abrasion, as well as clean removal properties.

Arming yourself with the right tapes for the job can help make quick work of prep work, resulting in containment preservation, passed inspections, time and money savings, customer satisfaction without call-backs, and on-time completion with minimal disruptions.

Shurtape, an industry-leading producer of pressure-sensitive tapes, offers a full line of tapes that are engineered for performance, even in the most challenging environments. Whether the job calls for excellent adhesion and holding power or easy hand-tearability and clean removal, these tapes deliver the product features you can rely upon to get the job done quickly and efficiently.

The latest innovation is DS 154 Double-Sided Containment Tape, a one-tape, one-step solution designed to save you time and money in prep work.

DS 154 is built with a differential adhesive system: on one side is a premium grade painter’s tape adhesive that delivers 21-day clean removal from a variety of surfaces; on the other side is an aggressive adhesive that securely holds poly-sheeting, plastic tarps and other protective coverings. For added efficiency and convenience, the tape and poly remove quickly together – in a single step – when the job is done.

Learn more about DS 154 Double-Sided Containment Tape – and Shurtape’s other tape solutions for the restoration, renovation, abatement and remodeling industries – at Shurtape.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!