The R&R Q&A: How Do I Know Wall Cavities and Hidden Spaces are Dry?

L: This is an example of a pin moisture meter, which you can insert into a wall creating minimal damage while getting a deeper moisture content reading.

Center: Pinless moisture meters are perfect for figuring out moisture content on a flat surface, like this hardwood floor.

R: Unlike pin meters, pinless meters do not cause any surface damage but, again, do not get the deep readings a pin meter can offer.

(Photo courtesy of Protimeter)

This is another example of a pin moisture meter, which you can insert into a wall creating minimal damage while getting a deeper moisture content reading.

(Photo courtesy of Lignomat)

Pinless moisture meters can accurately measure surface moisture without creating any damage.

(Photo courtesy of Delmhorst)

Pin moisture meters have probes like these that need just small holes in the surface to get a deep moisture reading.

(Photo courtesy of Protimeter)

Within this issue of R&R, we’ve talked about drying out spaces, when to demo, when not to demo, where to potentially place drying equipment, and so on. Drying is the name of the game in restoration, right? There is water damage in just about every restoration project. Even during fire restoration jobs, the home or business often needs to be dried to some extent after the fire department extinguishes the flames using hundreds of gallons of water.

So, how do you know all the tight, hidden spaces are dry?

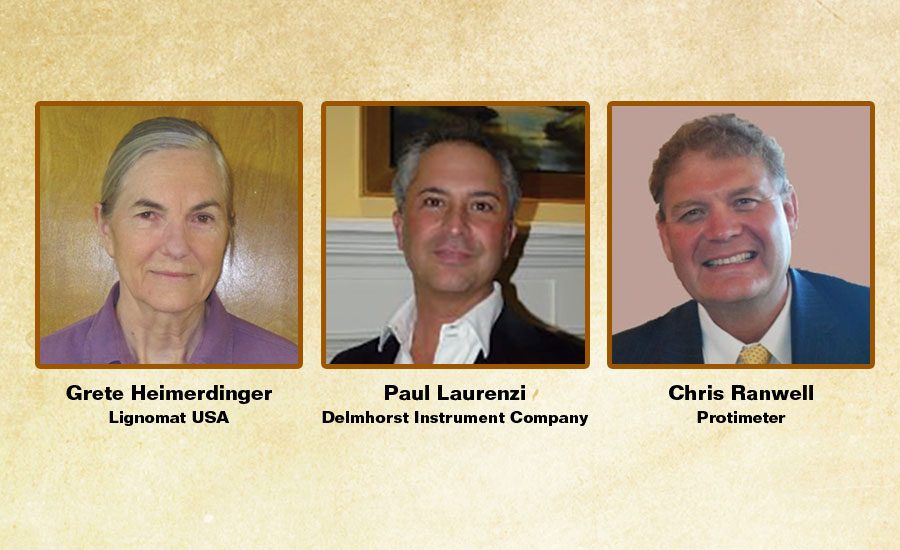

First off, allow me to introduce our panel of experts.

Grete Heimerdinger is a product manager at Lignomat USA, and has been with the company for more than three decades. The company originated in Germany, and expanded to the U.S. in 1979. Lignomat USA develops its own products to fit the American market.

Paul Laurenzi is the vice president of sales and marketing at Delmhorst Instrument Company. He is among the second generation of ownership and leadership in the company, which opened in 1946, and spends a lot of time traveling and educating restoration industry professionals on drying.

Chris Ranwell is the global product manager for gas and moisture products at Amphenol Advanced Sensors, including Protimeter. He has more than 21 years of experience with moisture meters and hygrometers and their use in flood damage restoration.

1. How can moisture meters & their accessories help specifically when drying a tight space or wall cavity?

Heimerdinger: You have to measure with a moisture meter to know it’s dry. In order to keep the cost down, you need to evaluate with a moisture meter so you can determine the size of the problem. The moisture meter will measure the material’s moisture content, and you can also measure relative humidity in a closed space. It is good to have a monitoring device that records the drying over time, so you can see the progress in wood, drywall, and so on. This is helpful when restoration companies want to know how effective their drying process is. For accessories, there are IR cameras around that also give an image of a problem, and the handheld moisture meter will give you a value for the problem. For measuring a tight space, you need something with enough reach – like a pin needle electrode.

Laurenzi: Pin type moisture meters are often better to use in a tight space or wall cavity because we offer different accessories that allow you to get into these places. For example, the use of a deep-wall probe allows the user to push the pins through drywall into the insulation behind to see if there is hidden moisture in the wall cavity. We offer a cable that attaches to the moisture meter on one end and has two alligator clips on the other. The user can attach any long metal “pin” to the alligator clips to extend the length and reach of the electrode to suit almost any need. For example, many contractors will use the alligator clip combination to check moisture under cabinets without having to remove the cabinet. Another tight space is between drywall and baseboard or under the sill plate. The 19-E/STC blade type electrode has two 4” blades that can be squeezed between the wall and baseboard, or under the sill plate to identify moisture in those hard to reach areas.

Ranwell: We recommend the use of non-invasive moisture measurement to find abnormal levels of moisture and for actual measurement and recording of the readings we recommend a more invasive method such as pins or probes. When trying to detect moisture in a wall cavity the only way is to use accessory probes such as insulated deep wall probes. These probes only measure at the tip and so two small holes are drilled into the drywall and the probes are inserted. This method allows the operator to find moisture deep into wooden studs or insulation material. For tight spaces, measurements such as sill plates in corners often a hammer electrode accessory allows the operator to access these areas where it may be impossible to get a hand held meter.

2. Can the use of the right tools save a restoration contractor time, and the insurance company money?

Heimerdinger: I work with a restoration contractor nearby and he says one of the things he likes is our moisture meters are accurate. He can remove the minimum area, instead of taking out a large area for a fleck of moisture. He can really determine what’s damaged and what’s not. That really saves the insurance company money to have a contractor who tries to not do the maximum damage and preserve what’s good.

Laurenzi: Absolutely – this is the whole key to using the right tools, such as a moisture meter. In fact the moisture meter is one of the most important tools in any restoration job, because it is the only way to identify the scope of damage prior to placing drying equipment. It is used daily to evaluate drying progress, and it has to be used before any drying equipment is pulled from the job site to ensure that that the structure is dry. Without the use of a meter, the technician is guessing at all of these things, which can cost both time and money to the restoration contractor and the insurance company.

Ranwell: Using accurate and durable moisture meters allows the restorer to quickly assess the building’s moisture- affected area. Fast responding hygrometers save time once during the assessment of all the psychometric readings that need to be taken.

3. How can a contractor be sure they are getting an accurate reading?

Heimerdinger: First of all, they have to use common sense. Check calibration, and understand the tool and the limits of the instruments. Will your meter read low enough? Follow the manufacturer’s specs before and after each job.

Laurenzi: The first step in ensuring accuracy is to buy a high-quality moisture meter that is designed and built for the rough environment of a restoration job. The better quality moisture meters have built-in calibration checks to allow the user to verify that the meter is in electrical calibration. The most important thing after calibration is to make sure the user understands the scale on the meter. For example, many moisture meters offer different scales for various building materials. If you are testing wood, but the meter is set to a drywall scale, the readings are going to be skewed.

Ranwell: Most quality moisture meters come with a calibration check device for the pin mode and the restorer should check their meter before each job.

4. What qualities should a contractor look for in a good moisture meter?

Heimerdinger: The good meters have a reference scale or percentage scale for measurements. The good meters clearly state that there is a difference in the measurements for different materials the meter is calibrated for. In a good meter, there is consistency, accuracy, and reliability in collaboration. The meter should also read the same hot as it does when it’s cold. Price is also something that kind of determines the quality. A $20 meter won’t perform the same as a $300 one.

Laurenzi: One of the most important qualities in a moisture meter should be durability. We all know how rough the environment can be and having a product that can withstand daily use in those environments is crucial. Contractors should also look for things such as the warranty of the product, the overall reputation of the company, and try to find out what kind of after-sales support the company offers. In addition, contractors should compare features on the meters, depending on how much information they want to gather. Things like different scales for various building materials, built-in calibration checks, data collection capabilities, are all great features intended to make the technician’s job easier and to ensure collection of solid data.

Ranwell: Accuracy, ease of use, durability, fast response and a minimum 2 year warranty.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!