Buying and Using a Handheld Thermo-Hygrometer for Restorative Drying

Hygrometers are an important part of the restorative drying process.

Since you are measuring so many different parameters, it’s helpful to have a fast-acting hygrometer.

Most meters now have some of these calculations built in, avoiding potential errors in using psychometric charts.

Measuring humidity accurately with long term repeatability has always been a significant challenge for sensor companies. At the core of that challenge is a good reference measurement from which to calibrate all sensors. Humidity chambers mix dry air and water vapor to create atmosphere and often this is further improved with an instrument like a chilled mirror dew point sensor.

These reference instruments and chambers are extremely expensive, cost tens of thousands of dollars and have an accuracy of ± 1%. The typical hand held meter used in restoration is a hygrometer with and accuracy ±2%, and this is achieved with meters with a cost of $600 or less.

The challenge here is significant for manufacturers. For many years, it was difficult to achieve this high level of accuracy with any reasonable longevity. In recent years, the advent of small polymer-based sensors produced in large volumes made the technology much more accessible to manufacturers of hand held meters. These sensors adsorb and desorb water vapor at a fast rate and once the capacitance across the sensor is measured a preloaded calibration calculates the relative humidity measurement.

Key takeaways

|

While most manufacturers use exactly the same humidity sensor, the key for optimum design and performance is the amount of airflow around the sensor. This is the key factor with regard to the speed of response of the instrument.

So what should you look for in a good hygrometer?

1. Accuracy and speed of response - Generally you “get what you pay for” when buying a hand held hygrometer. Lower cost hygrometers are often 3-5% in accuracy and take 10-15 minutes to properly settle. For instance, when measuring the effectiveness of a dehumidifier, large inaccuracies can mean the difference in knowing whether you are pulling water out of the air or not.

For restorative drying, it’s important to measure and record several measurements. These readings include the relative humidity and temperature outside the building, the unaffected area inside, the affected area and lastly, the output of the dehumidifier. These measurements take time as the temperature can range from the freezing point outside to well over 100 degrees F when you are measuring the output of the dehumidifier. Having a fast-responding hygrometer will enable the operator to save a significant amount of time over the life of the meter. So, a fast responding meter has a very quick payback.

A good practice is to take measurements in temperature order and be aware that if the unit is stored and/or left in a cold or very hot vehicle, the operator should start taking measurements closest to that temperature first. Change in temperature has a far bigger impact on instrument response time than humidity.

Choose a meter with a replaceable probe. Humidity sensors do not last forever and your hygrometer is a critical part of your operation. Sending the whole meter away for service or recalibration is not always an option, so simply replacing the probe means you are up and running instantly. It is also good practice to keep a spare sensor that will also act as a reference sensor to check all of your meters for accuracy.

2. Psychometric calculations – Most meters now have some of these calculations built in, avoiding potential errors in using psychometric charts. Look for meters that not only have grains per pound, but also other parameters like vapor pressure and enthalpy. Some meters have the capability to be remotely upgraded so, as drying science changes and new calculations are required, these can be added to the hygrometer with a firmware update just like a smartphone.

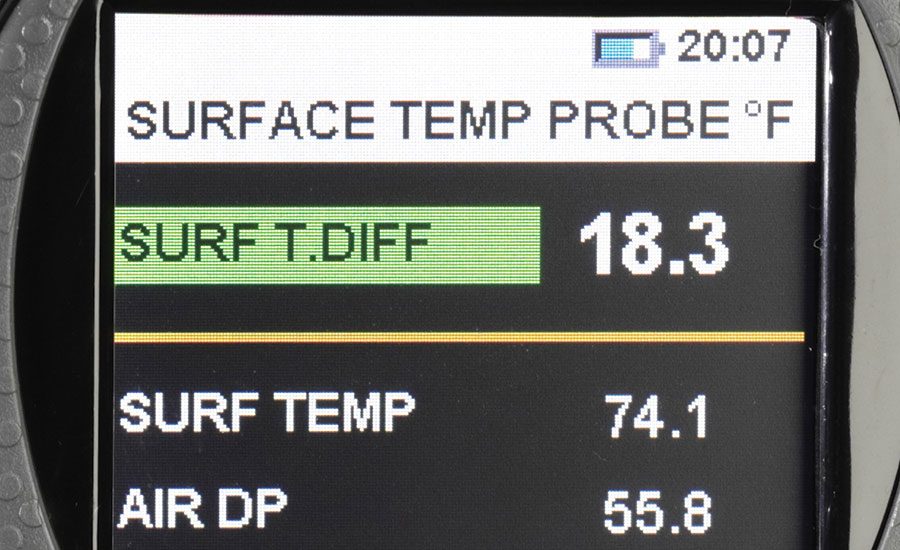

3. Surface Temperature – Many restorers are testing surface temperatures to ensure that wet materials have enough temperature for proper evaporation. Warmer surfaces dry better than cold ones, and new hygrometers have the ability to compare surface temperature to dew point. Surfaces warmer than dew point have energy available for evaporation; surfaces colder than dew point will condense water.

The capability of these meters to detect the risk of condensation on surfaces that can potentially cause secondary damage is a great benefit. Colder surfaces will start to form condensation first, and so it is important to monitor your surface dewpoint temperature. The introduction on non-contact infrared temperature sensors on some hygrometers allows operators to quickly assess the risk of condensation on any building material surface.

4. Simplicity – With multiple useful functions beyond relative humidity and temperature, it is important for the operator to be able to quickly understand and use the meter and so simple menus in different languages rather than symbols is often preferable.

5. Storing the meter – In order to get the fastest response from a meter, the sensor in the humidity probe often does not have a filter and so can be exposed to dust and dirt. Keeping the meter in a good case that is dust free will greatly extend the accurate life of your sensor.

6. Storing data – The ability to store data from single reading or be able to log data over time should be considered when making your purchasing choice. It’s often desirable to record this data for download later to avoid errors when recording data manually.

7. New Technologies -- Wireless hygrometers are often used for restorative drying and record keeping. They use the same measurement technology as handheld hygrometers and have the advantage of always being in temperature and humidity equilibrium reducing the time needed to take measurements when visiting a site. Some of these sensors systems can be incorporated with reporting systems for simple record keeping and remote viewing of the drying process.

As with any purchase for your company, it’s important to do your research and make an informed decision.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!