Using New Technology to Find Chemical Smoke Residue

Fire and smoke damage can be one of the most challenging remediation tasks. There’s the actual damage from the fire, which is relatively straightforward, and then there’s the smoke. Smoke can travel surprisingly far, especially when circulated by an active HVAC system or pushed by fast-moving air currents.

Most post-fire measurements and remediation efforts are focused on the smoke particulate (soot, char, and ash), but addressing these does not always remove the accompanying gaseous chemical contamination. The most crucial chemical components for long-term contamination are the volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs). These chemical constituents are primarily responsible for the characteristic smoky odor, the source of countless complaints, and many health concerns, especially regarding respiratory and eye irritation as well as more serious chronic conditions.

What can measurements show about smoke contamination?

Evaluation of the soot, char, and ash has long been the industry standard for smoke remediation because there are several methods that can be used to measure particulate contamination. However, there is little consensus regarding which specific method(s) should be used or agreement concerning what constitutes a clean or “smoke-free” level. IESO/RIA 6001 (Evaluation of HVAC Interior Surfaces to Determine the Presence of Fire-Related Particulate) provides some measurement guidance, but is limited to the HVAC system. ASTM D1506 determines ash content by measuring carbon black, but it is not always effective in smoke contamination assessments. The lack of universal methods and guidelines can lead to conflicting results based on which test is performed and which laboratory performs that test, leaving remediators with a lot of uncertainty.

The case is worse for chemical contaminants – there aren’t any guidelines at all. For a long time, the chemical residues were simply too difficult to measure or evaluate. Sometimes very limited chemical data was collected, typically acrolein concentrations, but this chemical indicator is only useful in certain situations and is not reliable for evaluating smoke contamination more than a few weeks after the fire occurred. Essentially, it was used because it was available, not because of the intrinsic value.

Recently, more comprehensive chemical testing to assess smoke contamination was developed by Prism Analytical Technologies, a company that has specialized in chemical measurement technologies for air for over 20 years. This method is based on the use of several chemical indicators that are relatively common to multiple types of fire and are uncommon in typical indoor environments. Incorporation of characteristic indoor chemicals is a key component to this method. Without accounting for these “normal” VOCs and SVOCs, it is far too easy to come to an incorrect appraisal of the amount of smoke residue present.

What’s so difficult about smoke VOCs?

It might seem as though cleaning up the smoke particulate should take care of the VOCs and SVOCs also, but they are part of different processes.

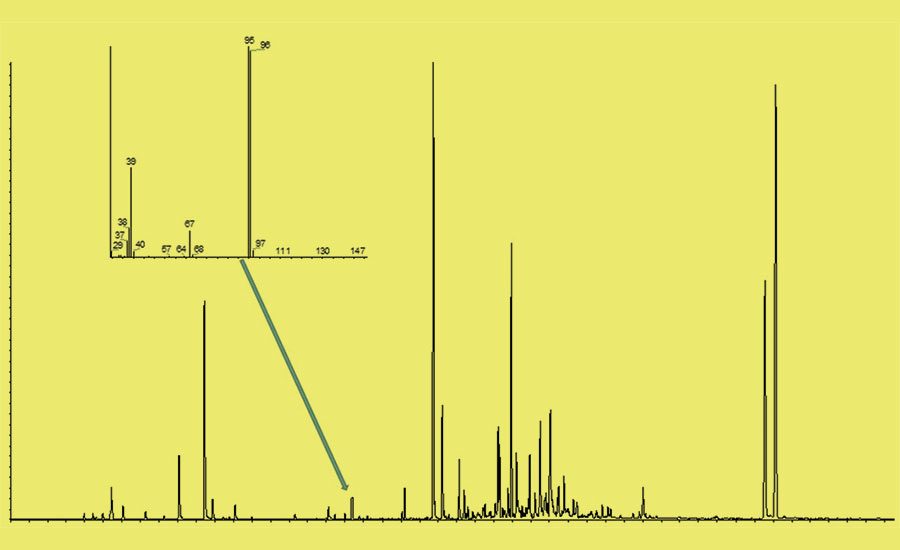

Fire is a result of combining fuel, oxygen, and heat and sustains itself with additional fuel, oxygen, and heat until one of these components is insufficient to maintain the fire. During a fire, the physical materials that burn (the fuel) decompose or break down, releasing soot, char, and ash, while the chemical components go through chemical conversion processes that produce an incredible variety of different types of chemicals. The large range of VOCs and SVOCs generated makes measurement challenging, especially since many VOCs and SVOCs created by a fire are the same as those that might be found in an unaffected indoor environment. Different fuel sources (e.g., structural framing, furniture, flooring, paint, fabrics, appliances, plastics, rubber, etc.) can change the type of chemicals formed. The smokiness of the fire also has an effect, tilting the distribution of the chemical types.

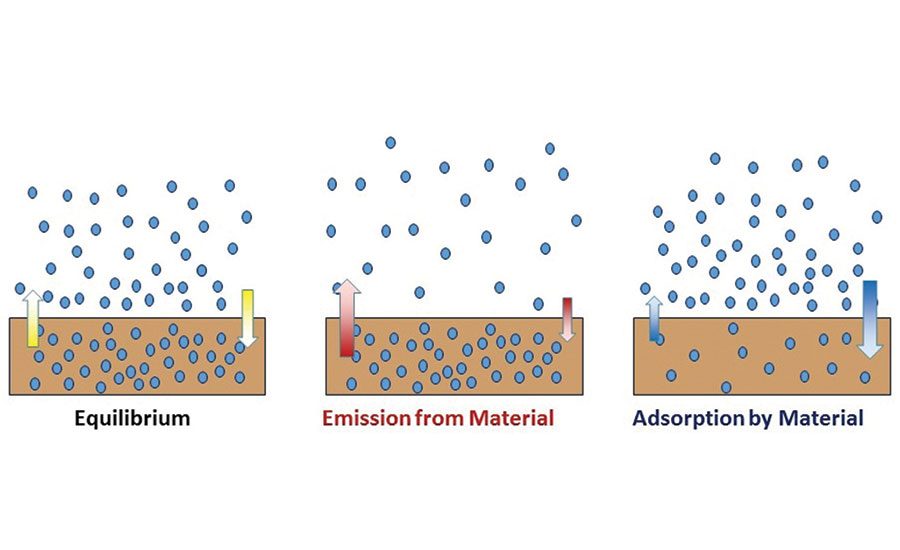

Gaseous chemical contamination can be tricky because it is not visible and may be more or less noticeable depending on the conditions, particularly temperature and humidity. These gases, both VOCs and SVOCs, are adsorbed into porous materials (e.g., carpet, foam cushions or padding, mattresses, fabrics, insulation, etc.) during the fire and subsequently form a balance, or equilibrium, with the gases still in the air. As that balance is disrupted, the gases either flow into (adsorption) or out of (emission) the porous material in order to rebalance their concentrations. So as time goes on and the VOCs in the air are removed by normal air exchange or specific clean up measures, the VOCs adsorbed into the material will slowly be re-emitted and may become noticeable months or even years later, especially on warm and humid days. This results in complaints about smoke odor.

Further complicating the issue is that although there can be a lot of smoke VOCs, their concentration is very low compared to all the otherVOCs in indoor air. For example, one home measured in late 2013 contained only about 0.2 percent smoke VOCs out of all VOCs in that sample. After cleanup or remediation, the VOCs often increase substantially as a result of new materials used to repair or renovate the damaged areas.

What does the new technology do?

Sophisticated laboratory instruments are used to identify specific VOCs and SVOCs that signify the presence of the chemical smoke residue. The different chemical types also provide information concerning the type of material (the fuel) burned during the fire and aid in determining how persistent the smoke residue might be, which also offers insight into the likelihood of recurrence of smoke odor later.

Samples are collected on-site and sent to the laboratory for analysis. The variability of chemical residues from smoke and individual situations means that the same sampling strategy may not be appropriate for every situation. Air and bulk material (e.g., carpet, heavy fabric, foam cushion or padding) samples are the most useful, providing insight into inhalation concerns in the case of recent fire and persistent contamination that could be a problem later for older fires, respectively. Other sample media may be useful in certain situations as well.

Assessment of fire and smoke damage, both before and after cleanup or remediation, can be a complex undertaking. Employing measurements of both particulate and chemical residues presents a much more comprehensive evaluation of contamination and aids remediators in implementing a more effective clean up strategy.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!